The company “Protechnology” started its work in 2009 – during the period of the most tangible for domestic industry phase of financial crisis. Having defined the priorities of the new times - cost optimization, searching the solutions that provide synergistic effects, rejecting unreliable partners and contracts that promise immediate benefits - the ProTechnology team entered the market of industrial equipment supply for metalworking production. During the first year of its operation the company has successfully established a key personnel and a portfolio of suppliers. The right choice of the strategy was proved by drawing landmark contracts with such state-owned enterprises as JSC "Klimov Plant", JSC "Luga Abrasive Plant", "K-Energo".

FROM THE FIRST PERSON

AND FRIENDS!

Victor Polyakov,

General Manager of

“ProTechnology” JSC

I am happy to welcome you from the pages of this presentation! Our company occupies a unique niche and is one of the most customer-oriented in the wide range of issues of servicing industrial corporations.

ProTechnology is a conscientious taxpayer, initiator and sponsor of humanitarian projects, prospective employer and, of course, a provider of industry know-how.

The history of the group of “ProTechnology” companies is a remarkable example of how together with the rise of the domestic industry a supporting business has developed and some institutions to support industrial infrastructure have been created.

Having surpassed the five-year milestone, we have chosen a course to increase the transparency of business - to meet the information demands of our customers and suppliers.

I sincerely hope that visiting our first interactive presentation will be useful and pleasant for You.

Yours respectfully,

Yours respectfully, Victor Polyakov

ABOUT THE COMPANY

equipment developing its own pilot production

and service on behalf of clients.

| Mission | Creating unique opportunities for development and modernization of the industrial infrastructure of Russia. |

| Development perspective | Achieving technological leadership, based on the use of advanced technologies, global experience of partners and intellectual potential of employees. |

| Values |

Customer focus Finding the most rational decisions and transparent criteria for their selection are the basis of competitive bids. The scale of company’s service capabilities provides the optimal level of coverage of customer needs. Promptness Prompt execution of its obligations is the hallmark and the key parameter of building business processes in ProTechnology. Reliability Strict adherence to industry standards and quality control of the phased implementation of project tasks form the solid foundation of reliability of services in ProTechnology. |

STRONG POINTS

| Integrated approach |

Vertical integration of business in "Protechnology" provides an integrated approach to solving design problems, from the formation of technical specifications to employee training on the customer side. |

| Diversified portfolio of brands |

The portfolio of ProTechnology company's suppliers has a high degree of diversification, which reduces the level of project risk and provides the flexibility of pricing policy. |

| Regional network |

The company’s regional network allows to respond quickly to market demands and to provide a high level of service. |

| Pilot production |

Actively developing production line of the business is equipped with modern material and technical base. |

| Staff | Protechnology adheres to modern standards in the field of human resource management. |

COMPANY HISTORY

| 2009 |

|

| 2010 |

In 2010 the marketing strategy "ProTechnology" was approved. The strategy takes into account the expansion in the major industrial regions of Russia and the promotion of corporate values of business in the leading industrial exhibition venues. During that period the company achieved a 30% increase in the portfolio of suppliers and the branch structure of customers was expanded. |

| 2011 |

The third year of operation was marked for "Protechnology" by the access to the market of Siberia. The company opened its headquarters in Novosibirsk, launched a program to develop a regional division team and formed a storage capacity. At the same time we continued to work on strengthening the competitive advantages and the company's image, which increased the volume of orders by 50%. |

| 2012 |

On the eve of its fifth anniversary "Protechnology" organized web welding production demanded in the North-West market. An affiliate network covering the dynamic Ural industrial cluster was deployed. “ProTechnology” held a series of meetings with leading European manufacturers: Wittmann Komet (Germany), Seiger (Germany), Fermat (Czech Republic), Gioria (Italy), which allowed to increase significantly the portfolio of suppliers and to expand potential opportunities. |

| 2013 |

In 2013, "ProTechnology" opened its second regional headquarters in Chelyabinsk - the largest industrial center with metallurgical enterprises, machine building and metalworking. Progressive development and the implementation of strategic guidelines allowed the "ProTechnology" company to enter the segment of Military industrial complex components (air defense and control systems), measuring gauges and tools and equipment for the oil and gas field. The average number of employees increased almost by three times, and the company's organizational structure was improved to meet new business challenges. |

| 2014 |

2014 became a new stage in the development of "ProTechnology": a production sector was founded in St. Petersburg, which allowed to carry out some specific orders on the machinery of turning and milling group, from pilot to medium parties, and to develop engineering solutions in practice. A redesigned website with a developed structure became another tool to promote the brand. |

| 2015 |

In 2015, “ProTechnology” invested into buildup of production facilities in St. Petersburg. The facilities were transferred to a new production site of more than 500 square meters, the equipment was built up, highly qualified professionals joined the team. The company continued to implement its expansion strategy to enter markets of Russia’s main industrial regions. In late 2015, a “ProTechnology”’s branch was established in a city of Kazan (Tatarstan). |

| 2016 |

In 2016, “ProTechnology” successfully increased the number of clients and expanded its network. A significant public funded contract was carried out for the Admiralty Shipyards. Cooperation was launched with BAYKAL company (brand Weinbrenner, Turkey), a large producer of sheet processing equipment, and Unimach company (St. Petersburg, Russia), a producer of laser beam machines. An office of “ProTechnology” was opened in a city of Nizhny Novgorod. |

| 2017 |

In 2017, the company’s main focus was on increasing production under the company’s brand ProTech. Cooperation with large producers of surface-grinding and milling equipment from Taiwan was launched. “ProTechnology” started production of forge-and-press equipment and machinery of bandsaw machines. WIVIA, a producer of Swiss-type longitudinal turning machines, became the company’s partner. Three new websites were launched: www.feedsystems.ru, www.pk-pt.ru and www.protechnolog.ru |

| 2018 |

“ProTechnology” signed an agreement on cooperation with PROMAU-DAVI, the leading global producer of plate roll bending and profile bending machines as well as automatic rounding machines. Investments into the expansion of production and storage facilities led to significant reduction in delivery terms and better meeting customers’ needs. The “ProTechnology” brand was present on global leading exhibitions among other industry leaders many times. |

| 2019 |

2019 was a year of jubilee to “ProTechnology”. The company continued its global activity to build and strengthen business relations with strategic partners. “ProTechnology” took part in biggest international exhibitions: TIMTOS in Taipei and EMO2019 in Hannover. “ProTechnology” was awarded the status of exclusive distributor of WIVIA’s longitudinal turning machines in Russia. |

| 2020 |

ProTechnology started 2020 year by setting a record: the amount of metalworking equipment in stock exceeded 200 million rubles. Despite widespread restrictions caused by the pandemic, the volume of the commissioning and start-up work increased by 30% this year. Moreover, the production company “ProTechnology” moved to Kolpino and expanded its production site up to 1600 m² at the end of the year. |

COMMITMENT TO SUSTAINABLE DEVELOPMENT

Guided by the principle of responsible business ProTechnology considers social responsibility as a necessary condition for sustainable development of the company. Being socially responsible for "ProTechnology" is taking care of customers, employees, helping to develop the regions of its presence.

Being a conscientious taxpayer of St. Petersburg ProTechnology makes a worthy contribution to the development of urban social projects. Developing a regional network, ProTechnology provides a stable growth of jobs and supports the economic potential of the regions of presence.

Implementing its charity projects the company is committed to revive the national tradition of mass chess playing. Supporting the chess in the regions is aimed to improve the intellectual level of Russian citizens.

One of the fundamental principles of sustainable development of the company "ProTechnology" is business transparency. Using the tools of marketing communications the company strives to provide data on how the company has evolved and what it aspires to. This presentation and the updated external website are aimed to provide customers, suppliers and potential employees with accurate and comprehensive information on the activities of the company over the past five years.

Carrying out its production activities and exploiting its objects PoTechnology complies with the established standards in the field of environmental protection. In its office spaces the company implements practices to ensure sustainable use of natural resources and reduce the environmental impact.

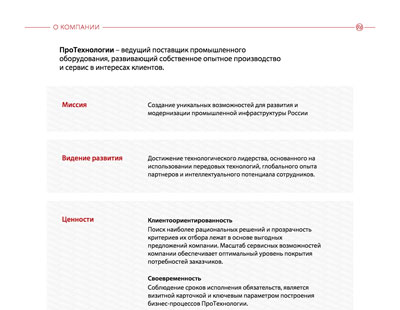

STAFF

The organizational structure of the company "ProTechnology" is formed with due account taken of the actual problems of increasing the capacity share of services with high added value, as well as creating opportunities to meet the needs of key customers.

The dynamics of the average number of employees in “ProTechnology” corresponds to the real expansion of the company's presence in the main segments of its activity.

The “ProTechnology” team has the experience of achieving their goals.

ProTechnology aspires to ensure that professionalism, commitment to high results and commitment to corporate values will be the only condition and guarantee of professional and personal growth of employees in the company.

BUSINESS OVERVIEW

The development of industrial infrastructure in Russia directly depends on fluctuations of macroeconomic parameters. The metalworking market forms a platform for industrial development.

In the wake of the industrial boom of the early 2000s the domestic market for metalworking equipment outpaced in growth rate many other segments of industry.

In 2009 the market for metalworking equipment faced a financial crisis and the sales of some market players decreased by 20% or more.

In its turn this provoked the emergence of new players focused on creating competitive quotations with consistently high quality of services. Thus, having determined the priorities of successful development ProTechnology began to actively explore the market opportunities.

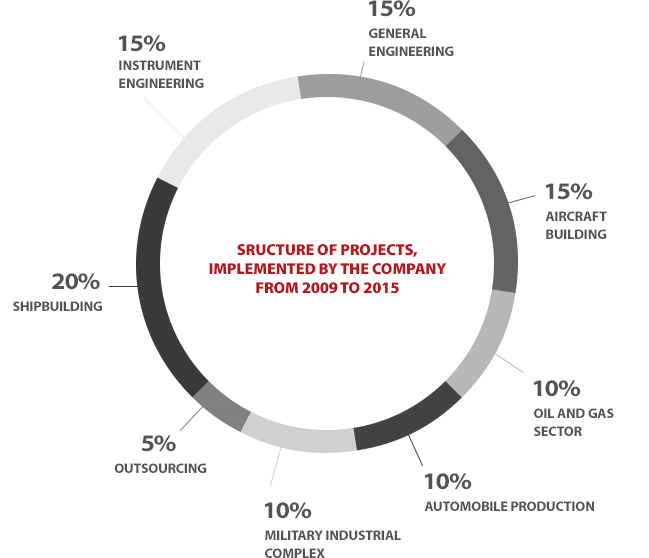

Years of experience and modern technological resources enable the company to successfully implement projects in such industries as automobile production, defense industry, oil and gas sector, shipbuilding and aircraft construction. The company also provides outsourcing.

EQUIPMENT SUPPLIED

|

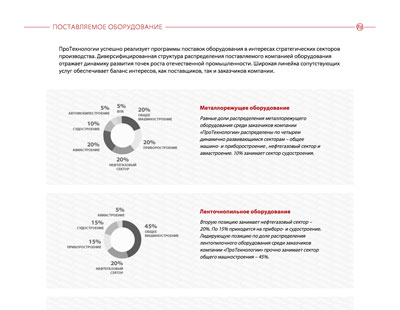

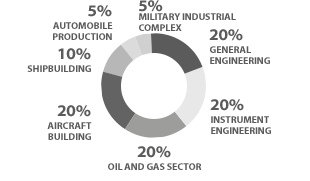

Cutting equipmentEqual shares of distribution of cutting equipment among the customers of the company "Protechnology" are divided into four dynamic sectors - general and instrument engineering, oil and gas and aircraft building. The shipbuilding sector takes 10%.

|

|

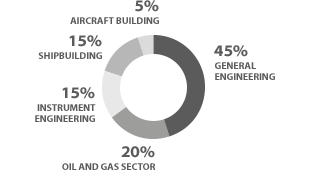

Band-saw equipmentThe second position is occupied by the oil and gas sector - 20%.Instrument engineering and shipbuilding take 15 % each. General engineering sector firmly holds the leading position among the customers of ProTechnology in the share of band-saw equipment distribution – 45%.

|

|

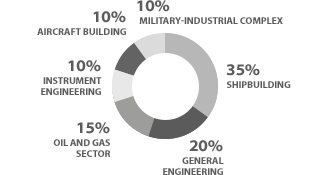

Welding equipmentWelding equipment is most demanded by the company’s customers representing the shipbuilding sector – 35%. General engineering and oil and gas sectors take 20% and 15 % correspondingly. Instrument engineering and military-industrial complex have equal shares in welding equipment supplies – 10%.

|

|

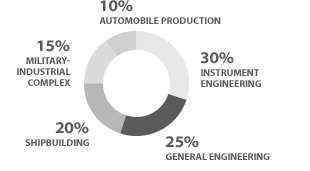

Sheet-working equipment(30% of all sheet-working equipment supplied by the company accounts for instrument engineering. At the same time 25% and 20% are taken by general engineering and shipbuilding correspondingly. Military-industrial complex takes 15% of sheet-working equipment.

|

RELATED SERVICES

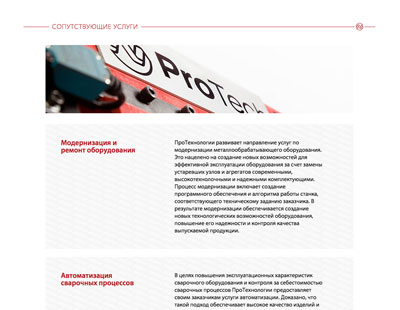

| Modernization and repair of equipment |

ProTechnology is developing its services for modernization of metalworking equipment. It is aimed at creating new opportunities for the effective operation of the equipment due to replacement of obsolete components and assemblies by modern high-tech and reliable components. Modernization process includes the creation of software and the algorithm of a machine according to customer's specifications. As a result, modernization provides generation of new technological capabilities of the equipment, improvement of its reliability and product quality control. |

| Automation of welding processes |

In order to improve the performance of welding equipment and to control the cost of welding processes ProTechnology provides its customers with automation services. It is proved that this approach provides high quality products and customer’s resource optimization. |

| Automation of progressive stamping lines |

In the interests of its customers ProTechnology provides services of automation of stamping lines. The introduction of automated lines in the production cycles of the enterprise provides a high level of performance and reduces the influence of the human factor. |

| Production of parts according to customers' drawings |

Taking into account the market demand for the design of unique details ProTechnology is actively developing its competence in producing parts based on customers’ drawings. The company pays special attention to this activity, the investor in development of the manufacturing base, deepening industrial expertise in various projects. |

SERVICE MAINTENANCE

Building long-term and trusting relationships with its customers and suppliers the company strives to maintain an appropriate balance between the interests of each party. To meet the cycle needs of its customers ProTechnology is successfully developing the equipment warranty support which is able to provide its performance over the entire lifetime.

Taking into account the specific character of industrial use of the supplied equipment ProTechnology is increasing its range of service capabilities beyond the warranty guidelines. The company’s attention is focused on the areas of advisory services and after-sales support.

Also as part of service maintenance ProTechnology offers the market the replacement of removable units and parts that are out of order.

Moreover, a wide range of suppliers allows the company to guarantee its customers the possibility of supplying spare parts for all the pieces of equipment within the area of specialization of "ProTechnology".

In its turn this diversified service approach has been appreciated by our foreign and domestic partners, whose reputation of being reliable manufacturers of equipment is crucial.

CUSTOMERS PORTFOLIO

JSC “Admiralteiskie Verfi”

St. Petersburg

JSC “Luga Abrasive Plant”

Luga, Leningrad region

JSC “KAMAZ”

Naberezhnye Chelny, Tatarstan

OJSC “Power Machines”

St. Petersburg

PJSC “NGO “Volna” Factory”

St. Petersburg

«PERco» Company

St. Petersburg

LLC "ACACIA-avia"

St. Petersburg

JSC "Akron"

Veliky Novgorod

LCC "Baltic Shipbuilding plant"

St. Petersburg

CJSC "Sokol-ATS"

Belgorod

JSC "Severniy press"

St. Petersburg

JSC "Klimov"

St. Petersburg

JSC “Kozitsky Plant”

St. Petersburg

CJSC "REP Holding"

St. Petersburg

CJSC “Okulovsky furniture accessories factory”

Okulovka, Novgorod region

"Brigantina" Ltd.

St. Petersburg

JSC "GOZ Obukhovsky plant”

St. Petersburg

JSC «Automobile van complex"

Shumerlya, Chuvash Republic

JSC "Experimental boiler and turbine plant"

St. Petersburg

OOO "Experimental Plant of building structures"

Gatchina, Leningrad region

CJSC «BARS"

St. Petersburg

CJSC "Industrial Company “Heat transfer technology"

Ozersk, Chelyabinsk region

FSUE "Leningrad Northern Factory" St. Petersburg

St. Petersburg

CJSC “Geser”

Otradnoye, Leningrad Region

JSC "Leningrad Shipyard "Pella"

St. Petersburg

CONTACT INFORMATION

| Head office in St. Petersburg |

|

196084, St. Petersburg,

Novo-Rybinskaya St., 19-21, of. 218 Telephone/Fax: +7 (812) 318-75-58

|

| Representative Office in Moscow |

|

117405, Moscow,

Dorozhnaya St, 60 B, office 639 Telephone/Fax: +7 (495) 640-04-44

|

| Novosibirsk branch office |

|

130108, Novosibirsk,

Stantsionnaya St, 30А office 115 Telephone/Fax: +7 (383) 399-11-09

|

| Nizhniy Novgorod branch office |

|

603086, Nizhniy Novgorod,

Kerchenskaya St., 13, office 316 Telephone/Fax: +7 (831) 422-26-88

|